We manufacture, under licenses from the U. S. Naval Research Laboratory (NRL), a complete line of Fluorinated Polyurethane FPUTM coatings for Architecture & Engineering.

Like most fluorinated polymers, FPUTM provides a non-stick, low surface energy finish that resists soiling, is extremely stable (resistant to UV and solvents), is chemically non-reactive (nontoxic and suitable for potable water applications), and is impermeable to oxygen and water (provides a superior anticorrosion barrier).

Unlike most fluorinated coatings, however, FPUTM does not require heat curing. The two-component (chemically curing) NRL formula makes it possible, for the first time, to apply FPUTM in an economical thin film, using conventional painting equipment. Our coatings are also strong, flexible, and abrasion resistant, because during the ambient-temperature curing-process, the polymer molecules cross-link to form a mechanically tough surface.

These properties result in the following advantages.:

These properties translate into improved appearance, and lower cost of ownership because, FPUTM coatings reduce: the need for maintenance, the maintenance effort, and the maintenance downtime.

We manufacture several versions of our WCTM Series topcoats to preserve a structure's appearance and to protect it from corrosion in a number of different environments.

FPU WC-1 provides basic, cost-effective FPUTM protection in a normal environment. The first picture on this page shows WC-1 used to preserve the appearance of a high-impact area (the water wall) at the Sidney Casino.

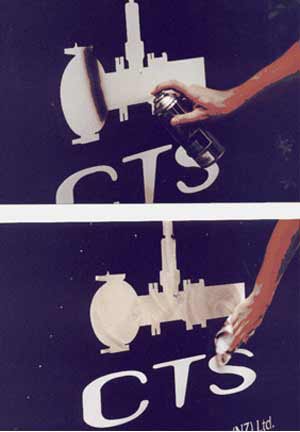

FPU WC-1 (BA) is variant of our basic WC-1TM that includes additives that produce a surface that is very resistant to soiling by common graffiti agents. Stains do not penetrate the surface and clean off without leaving a shadow. The second picture shows a test at the Australian Post Office.

FPU WC-2 (H) is a version of our WC-2 TM Series, which provides an intermediate level of fluorination for added mechanical toughness. WC-2 (H) TM also contains PTFE, which produces a finish with very low surface energy. Low surface energy means that there is very little energy available with which a soiling agent to form a bond with the surface. That is, the surface is very resistant to soiling and can be cleaned easily, often with water-pressure only. The next two pictures on this page show WC-2 (H)TM on exposed structures in Westchester County, New York.

FPU WC-15 is heavily fluorinated to provide enhanced mechanical toughness, UV resistance, and protection against salt-water corrosion in the most extreme environments. It is Lloyds certified (MATS/2481/1) for Salt Water Ballast Tanks. The last picture on this page shows WC-15TM used on a sea-water intake structure at a petrochemical plant.

A typical system for steel is as follows:

A typical system for concrete is as follows: